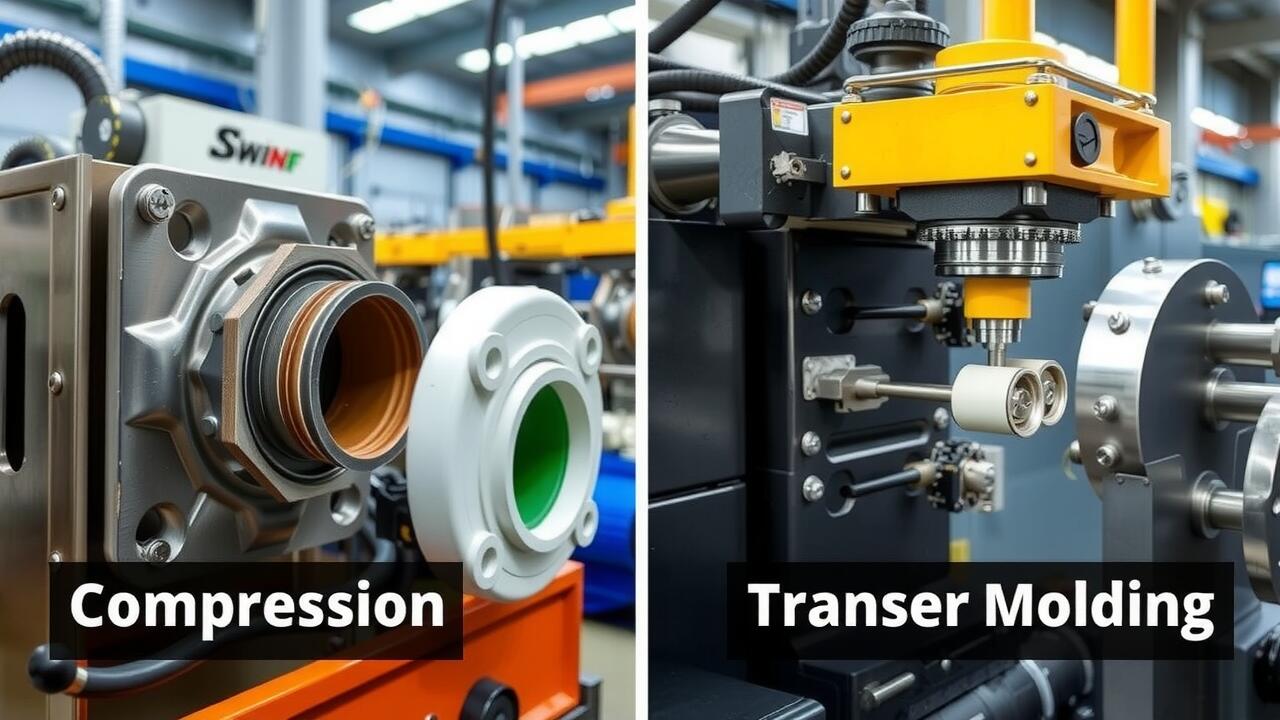

Comparing Compression vs. Transfer Molding for Low-Volume Rubber Components

Table Of Contents

Material Compatibility in Molding Methods

Choosing the appropriate molding method greatly depends on the material properties of the rubber used. Compression molding is often favored for its efficiency with thicker materials and has a strong capacity for various elastomers, including natural rubber, silicone, and neoprene. This method offers cost-effectiveness for low-volume production runs of OEM molded rubber parts. In contrast, transfer molding provides better control over material dynamics, making it suitable for more intricate designs and rubber compounds that require precision. For instance, when producing RPM Rubber Parts, transfer molding ensures that the intricacies of the components are maintained without compromising on quality.

Understanding the compatibility of rubber types with different molding processes enhances overall production efficiency. Compression molding tends to work well with materials that exhibit lower viscosity, facilitating easier flow into the mold cavity. Conversely, transfer molding suits compounds with higher viscosity that may otherwise struggle with the flow characteristics required in compression processes. Manufacturers often analyze the specific requirements of components, assessing factors such as tensile strength and temperature resistance to guide their method selection. As a best practice, thorough testing and validation during initial production runs can prevent costly defects and improve yield rates in both molding techniques.

What Types of Rubber Are Best Suited for Each Molding Technique? (evaluating material properties)

Natural rubber, known for its excellent elasticity and tensile strength, pairs well with compression molding. This method applies consistent pressure, allowing the rubber to flow into intricate designs, which is particularly beneficial for creating OEM molded rubber parts that require precise dimensions. In contrast, transfer molding shines with thermosetting rubbers like silicone, which require heat to cure effectively. Features such as high-temperature resistance and stable mechanical properties make it ideal for applications where durability is critical, such as in components exposed to extreme conditions.

For both methods, evaluating the specific characteristics of the rubber is crucial. For example, the viscosity and flow properties of a rubber compound greatly influence the choice of molding technique. Companies like RPM Rubber Parts optimize manufacturing by selecting the appropriate molding process based on material performance. It's often beneficial to conduct preliminary testing to ensure that the selected rubber can withstand production stresses while meeting desired specifications. Using material data sheets during this phase can assist in understanding compatibility and performance under various conditions.

Quality Control Measures in Molding

Quality control in molding processes serves as a critical component for ensuring the reliability and performance of both compression and transfer molded parts. Implementing a robust inspection regime based on industry standards can significantly minimize defects. For instance, organizations often adhere to ISO 9001 standards, which provide a framework for quality management systems. Testing can include dimensional verification, hardness testing, and visual inspections to identify surface imperfections. Consistency in rubber material properties directly affects the molding process outcome, thus thorough testing becomes essential, especially when dealing with OEM molded rubber parts that demand high precision.

Adopting statistical process control (SPC) methods also enhances quality monitoring throughout the production cycle. This data-driven approach enables manufacturers to analyze process variations in real-time, allowing for immediate corrective actions to minimize waste. A case study from RPM Rubber Parts highlights how implementing SPC reduced defect rates by 25% within six months. Regular maintenance of machinery and adherence to operational guidelines further supports quality retention. Troubleshooting common issues related to curing times and material flow can significantly impact overall product integrity. Continuously optimizing these factors will contribute to producing reliable and high-quality low-volume rubber components.

5 Key Strategies for Ensuring Quality in Compression and Transfer Molding (testing and validation)

Quality assurance is vital in both compression and transfer molding processes. Implementing rigorous testing protocols ensures that the final products, such as OEM molded rubber parts, meet specifications consistently. One essential strategy includes utilizing statistical process control (SPC), which helps monitor the production process. Implementing SPC techniques can decrease defect rates by up to 25%, providing a more reliable way to track variations during the molding cycle. Additionally, conducting regular material inspections before and after the molding process can prevent issues related to material compatibility and consistency.

Another effective strategy is implementing a standardized validation procedure for molds and tool setups. This includes using certified gauges and tools to measure key dimensions before production starts. For instance, employing contact or laser measurement systems can detect deviations as small as 0.001 inches, which can be crucial for precision components. Collaborating with suppliers like RPM Rubber Parts ensures access to high-quality raw materials. Furthermore, establishing robust feedback loops allows for real-time adjustments based on testing data, significantly enhancing production efficiency and product quality.

Common Issues Encountered in Molding

Manufacturers often encounter several issues when working with low-volume rubber production. One common problem is incomplete cure, which can lead to parts exhibiting poor mechanical properties. Inadequate temperature control during the curing process can exacerbate this issue, particularly in transfer molding where precision is essential. For example, a case study revealed that an OEM rubber parts manufacturer suffered from high rejection rates due to insufficient heat distribution in their molds, leading to a 25% increase in production costs.

Another frequent challenge involves surface defects that manifest as flash, voids, or misalignment. These defects not only compromise the aesthetic quality of the parts but also affect their performance. An investigation into a specific incident demonstrated that using subpar materials during the compression molding process contributed to excessive flash on molded components. Random testing protocols and regular maintenance of equipment, as suggested by industry best practices, can mitigate such issues. By regularly calibrating machinery and establishing robust quality control systems, companies like RPM Rubber Parts can enhance the reliability of their OEM molded rubber parts.

What Are the Most Frequent Problems in Low-Volume Rubber Production? (defects and troubleshooting)

Defects in low-volume rubber production often stem from variations in temperature and pressure during the molding process. These fluctuations can lead to issues such as incomplete curing or uneven material distribution. For example, if the temperature is too low, the rubber might not fully cure, resulting in a weak final component. Likewise, excessive pressure can cause over-compression, leading to material flash or distorted shapes. Maintaining consistent parameters is crucial; as studies have shown, a mere 10-degree variance in temperature can alter the properties of OEM molded rubber parts significantly.

Another frequent issue is the selection of incompatible materials for specific applications. When manufacturers use rubber compounds that do not meet the requirements for the intended application, performance issues arise. A study indicated that nearly 30% of defects in prototypes stem from poor material choices in the early design phase. RPM Rubber Parts has emphasized the importance of matching compound characteristics to application needs, recommending thorough testing under real operating conditions. By ensuring compatibility between the rubber compound and the environmental variables encountered during use, companies can mitigate many defects in their production processes.

Selecting the Right Molding Process

Selecting a suitable molding process hinges on various factors, including production volume, complexity of design, and material characteristics. Compression molding often accommodates simpler geometries and larger parts efficiently, making it a prime choice for OEM rubber parts where high volumes are not essential. For instance, industries producing gaskets or seals frequently employ this method due to its lower initial setup costs and faster cycle times. Conversely, transfer molding shines in scenarios demanding finer detail and more intricate designs. This method facilitates tighter tolerances, ideal for applications in the automotive industry, where precision in OEM molded rubber parts can significantly impact performance and safety.

Evaluating your production needs thoroughly can lead to optimized decision-making. Consideration of part size and complexity plays a crucial role; if you require multiple materials or colors, transfer molding is more versatile. Additionally, assess the technical specifications required for your components. For instance, RPM Rubber Parts exemplifies effective use of both techniques based on client requirements. They successfully deliver parts that meet stringent industry standards while maintaining short lead times. Engaging with a knowledgeable supplier can provide insights into best practices for both processes, ensuring that the selected molding method aligns with both manufacturing capabilities and project goals.

How to Decide Between Compression and Transfer Molding Based on Your Needs? (factors to consider)

When deciding between compression and transfer molding, companies must consider factors such as design complexity, production volume, and cost constraints. Compression molding excels in producing large, simple components efficiently, making it a preferred choice for OEM rubber parts with straightforward geometries. For instance, a manufacturer needing high tensile strength and durability in rubber seals might find compression molding advantageous due to its cost-effectiveness at low volumes. In contrast, transfer molding is better suited for intricate designs and applications requiring precise dimensional tolerances, such as automotive gaskets, where the need for intricate flow paths is critical.

Another key aspect to evaluate is the material compatibility. Certain formulations of silicone rubber or EPDM may demonstrate enhanced performance in transfer molding due to their ability to flow better under heat and pressure. This leads to improved detail in molded parts. Companies like RPM Rubber Parts have successfully adapted both techniques to meet diverse customer needs, demonstrating that selecting the right process can significantly affect production efficiency and product quality. Careful analysis of project requirements and mold capabilities can guide manufacturers in choosing the optimal method for their specific application, ensuring the final product meets industry standards and customer expectations.

Conclusion

Choosing the appropriate molding process for low-volume rubber components hinges on several critical factors, from material compatibility to production efficiency. For instance, compression molding is often preferred for larger parts, thanks to its straightforward tooling process that can result in lower production costs. In contrast, transfer molding may be more advantageous for complex shapes or when tighter tolerances are paramount, as it allows for more precise material flow and better surface finishes. Understanding these nuances can significantly impact both the quality and cost-effectiveness of OEM molded rubber parts.

Ultimately, the decision between compression and transfer molding should be guided by specific production requirements, material properties, and potential challenges. Companies like RPM Rubber Parts exemplify how selecting the right method influences overall production success. By carefully evaluating factors such as cycle times and defect rates, manufacturers can optimize their processes while ensuring that each component meets stringent industry standards. Identifying the right fit fosters efficiency and contributes to maintaining high-quality standards in an increasingly competitive landscape.